Would you like more information about a product? Query

Manual and CNC hydraulic horizontal bending machines, bending presses, straightening machines and presses, and turning devices for welding

Stierli-Bieger AG designs and builds well-conceived manual or CNC controlled horizontal bending machines, cambering & straightening machines (straightening press) and turning devices. The first bending machine was produced in 1936 and has undergone continuous development ever since. Today Stierli-Bieger AG is a world market leader in horizontal bending press and straightening- and cambering machines. Our customer base includes the metal processing industry and well-known steel producers, switchgear producers (busbar bending machines), machine, ship and rail manufacturers throughout the world.

- hydraulic horizontal bending machines

- Bending presses and horizontal press brake (manual or CNC)

- Straightening machines

- Straightening presses

- Turning device & turning devices Rotator

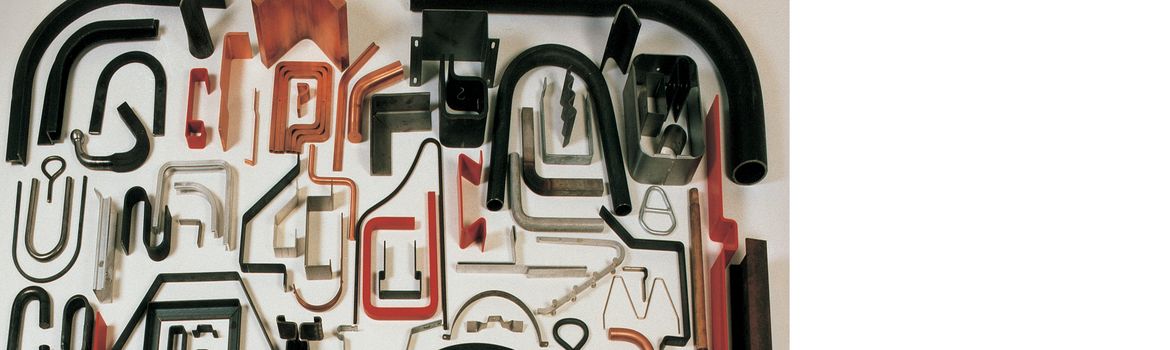

Universal bending machines and straightening machines for the most varied tasks in general metal processing and sheet metal working

Our models cover a wide range of work force. We manufacture various models of machines with hydraulics with a straightening and bending capacity from 8 tons to a maximum of 900 tons. Companies in the metalworking industry appreciate our robust standard machines as well as our competence and experience in the production of special machines such as steel bending machines or bus bar bending machines. With our own construction department we are able to manufacture horizontal folding machines (hydraulic sheet metal bender) or straightening machines adapted to your needs in metal processing. With our modern control system engineering, we consistently drive innovations that increase the possibilities and efficiency in metal bending and straightening. The design of our control system ranges from the proven and easy to use manual control system to digital CNC control, with connection of the bending machine to a bending robot. The CNC bending machines correspond, depending on the version, to a top modern bending center, which contains graphic displays of the current bend, bending angle, radius, total length, and bending sequence simulation. The bending machines are also available with an active angle measurement as an accessory.

The models of the horizontal press brakes have hydraulic drives, the radial benders (angle benders) have motorized electric drives.

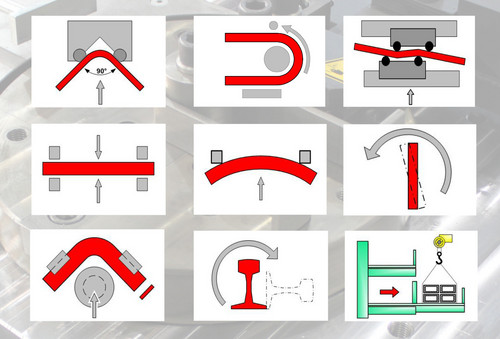

The tooling technology offers a wide variety of production possibilities to fulfill the various tasks for bending and straightening steel and metal in general metal processing, sheet metal processing with sheet metal bending machines and mechanical engineering. For example, sheet metal and standard bent parts can be bent with standard bending tools with V-opening. Bending flat steel or round steel is possible with our machines without any problems. These standard tools are available with different working widths and heights depending on the machine model. With forming tools and press bending (also known as stamping bending), bent parts can be economically produced in series with only one single bending stroke. Additional tools such as tube bending segments make the Universal Stierli press brake a tube bending machine that can be used to bend tubes (without mandrel). In combination with the proven Stierli straightening control and corresponding straightening tools, the use of the machines for straightening can be extended to achieve an optimum of application possibilities from the bending capacity. This universal use allows an optimal price-performance ratio to be achieved when working in the workshop.

Discover the different systems for bending and straightening on our website via navigation. We have numerous videos which illustrate the bending or straightening process and are available to you. If you are interested, we would be pleased to send you pictures or online videos.

The models of the Radial Bender with its principle of rotary draw bending can also be used as a folding bending machine for thick metal bending, or as a round bending machine or ring bending machine for bent parts with different radii and bends (without three or four rolls), depending on the design and type of the tool installed. The smaller horizontal ram bender as a mobile version with manual control and a compact worktable (and small footprint) very often replaces in practice manual bending machines or a hydraulic tube bender. These are usually available from stock.

We are optimally networked in the market worldwide with our representatives in the machine trade and can offer you competent advice (free of charge) from professionals, top support and smooth shipping before and after the purchase of a new machine. You will find us at many large machine exhibitions in Germany, Austria, Switzerland, France, Belgium, Holland, Spain, Poland, USA United states, Russia, Australia and South America etc..

Are you interested in our models, products or our individual straightening or bending solutions? Or are you looking for a suitable machine for a specific application for bending or straightening? We look forward to hearing from you by phone, e-mail or our contact form. We are also available for tests. We will be pleased to send you non-binding information, offers and prices for our bending machine. So that we can provide you with optimum support even before you buy, customer proximity is very important to us.

You are always welcome to visit us. We would be pleased to present the variety of our models and products to you personally and look forward to advising you. We are very easy to access for our guests and are ideally located near a motorway. The two airports Zurich ZRH and Basel BSL are only 1h away. On your desire we can also pick you up at the airport.

Our company stands as a manufacturer for high-quality, robust and innovative technical products and machine solutions. Translated with

stierli-bieger.com

stierli-bieger.com